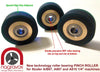

Pinch Rollers for Studer and Revox 1/4" recorders

Nagravox offers 4 different types of pinch rollers (PR) for the majority of later Revox and Studer ¼” machines. Two different rubber materials and two central bearing / bush assemblies options are offered. Our pinch rollers are made specifically for us to our specifications in the EU – NOT China.

Suitable for:

REVOX A700 B77 PR99 C270 STUDER A807 A810 A67 B67

A selection of shims and PTFE low friction washers in a variety of thicknesses are always provided for fine tuning the fitting of the pinch roller.

Pinch rollers have a prime purpose to maintain rigid even pressure of tape against the capstan without slippage. They come in two different rubber formulations and differing central hub configurations.

Green and translucent beige Adiprene (ADP) are urethane based formulations. They are a little easier to machine once potted and have a long life. They have excellent rigidity and profile conformity. However, they are sensitive and can degrade quickly if exposed to solvents and fluctuating high / low temperatures. They are a little more difficult to clean of thick tape residue.

Black pinch rollers have similar capabilities and are made of black synthetic rubber. They are slightly more demanding to fabricate (machine / grind) but very stable and have a long life.

Which is better? At the end of the day, neither when they are manufactured properly and most importantly they are looked after and changed at reasonable intervals. Both formulations used in Nagravox pinch rollers are carefully determined and controlled so as to maintain surface contact rigidity and minimise wow and flutter over their lifetime.

Hard and Soft PR’s. Contrary to popular belief, the PR should be quite hard and ‘rigid’ - and definitely not soft or pliable. It should NOT deform around the tape in the mistaken belief that this helps the capstan drive the PR. The PR does not drive the tape! The PR's function is to apply an even pressure against the tape on the capstan shaft thus ‘braking’ its passage from left to right across the heads. This is a stabilising function of the tape tension system between the left and right reels. The capstan thus acts as a regulator rather than a driver. So, it is important to have the PR as evenly rigid with the criteria being an even pressure against the tape so as to minimise any dissonance between driving and regulating. A compromise between hard and soft is thus called for. Hard to minimise pinch roller deforming and being driven by the capstan and soft enough so that at the pressure point an even maximised contact area is realised. A very soft PR can increase wow and flutter as well as 'pick up' tape residue. A soft PR will also start to degrade quicker in terms of conformity after repeated cleaning.

The central metal part – bush. Most pinch rollers are of sintered bronze construction. Sintered bronze bearings have long lives. The shaft is hardened steel / stainless steel and the sintered softer sintered bronze bush preferentially wears, adapts and self lubricates. Look after it and it will last many years. The lubricant for the life of the PR is actually contained within the sintered micro pores. DO NOT lubricate a pinch roller.

Roller bearing pinch rollers. These have one or two roller bearings. They are very quick and simple to install and usually dont require shimming. Friction is less that the bush type, wear on the shaft minimal and any uneven clearance minimised if the shaft is worn. Nagravox roller bearing pinch rollers are an ideal solution to those situations where you suspect the pinch roller shaft may be worn. Worn shafts on Studer machines at high speed may be accompanied by a squeaking noise during play. The pinch roller shaft is not easy to replace on most models. In testing we have found no difference between the deluxe and standard bush pinch rollers in wow and flutter, so neither one is ‘better’. One disadvantage is that a bearing assembly uses the maximum height available and cannot positioned by shimming top and bottom. Some vendors on ebay make silly claims for the bearing based pinch rollers which frankly are just mumbo jumbo and do not translate to tangible benefits in reality. The life of a bearing based PR is somewhat less than a bush type and will require replacing more often when they become noisy

HOW GOOD ARE “OTHER” PINCH ROLLERS?

I don’t wish to criticise competitors but here are some of our observations. We make no excuse for our pinch rollers more traditional design and cost which is more expensive. You get what you pay for. We mark up our PR’s minimally and fairly. They are not a big profit item and I wont get into a price war. Our pinch rollers are made specifically for us to our specifications in the EU.

In the last few years there has been a significant increase in offerings of

· Soft ADP pinch rollers

· Slip on pinch roller tyres

· Cheap pinch rollers made in China. Indeed almost an explosion of offerings!

Soft Adiprene (ADP). The pinch roller surface needs to be fairly hard and ‘rigid’ – not easily deformed. The soft white or translucent adiprene on some pinch roller offerings seem to be less stable and are developing a reputation for not lasting long.

Pinch Roller Tyres. These are not precision machined at all and are cheap inferior slip on’s that are frankly a joke.

Made In China – dirt cheap! Problem is they are just poor quality copies. Dubious dimensionality / out of spec and often do not even use the correct sintered bronze for the inner journal. We have tested and continue to test and evaluate. I would love to find a high quality Chinese manufacturer! So far they are just not worth it. Maybe one day.

SOME USEFUL INFORMATION

Is the tape in the middle of the PR profile? Often it is not. Nagravox PR’s for Studer and Revox ¼” machines have a slightly decreased height / thickness that allow a degree of shimming top and bottom to help you ensure that the tape is in the middle of the PR. This we feel is important to setting up a pinch roller correctly and will minimise wander, wow and flutter.

Capstan shaft shiny. Revox, Studer and many later Japanese machines used a special micro bead blasting process to dull the capstan shaft to give better grip on the tape. This improves contact so that lower PR pressure could be used. A technical bulletin to this effect was issued by Studer and a good reason to consider getting your capstan shaft re-surfaced / re-conditioned. Nagravox now offers this service. NEVER EVER try to ‘rough up’ the capstan shaft with sandpaper – you will ruin it. Some idiots on www forums actually advocate this – its crazy!

The correct PR pressure is important. Adjust exactly as per manufacturers instructions. More is not better! Revox machines have a greater degree of adjustment possible whereas Studer machines have a different but more robust mechanism, which has less facility for fine adjustment unfortunately.

Tape tension is also extremely important because the PR / capstan is a regulating system not a driving system.

Using old or NOS tape. All tape sheds oxide to a lesser or greater extent. Old tape sheds it a lot, which clogs up the pinch roller, heads and tape transport system. This is the biggest cause of poor performance. SIMPLE. Don’t buy or use 2nd hand or NOS tape – its rubbish.